-

Particle size

reducting

Size reduction is an everyday process in the food industry as well as in the chemical, cosmetic and pharmaceutical industries. Basically, the aim is to reduce the particle sizes of the different starting materials by using suitable processes and technologies. Thus, either the characteristics of the starting materials are purposefully changed (texture, taste, brilliance etc.) or their reactivity (e.g. API) is positively influenced.

ProXES has specialized in wet cutting. This means that the products to be shredded must be flowable, pumpable or have a certain residual moisture. Our portfolio offers five different technologies for cutting, which individually or in combination cover a wide range of particle sizes - from several centimeters of initial size to target sizes of a few micrometers, in special cases even nanometers. These technologies can also be used to cut and disperse fibrous starting materials, keyword: milk derivatives.

Our experts for cutting:

Microcut 15

Perfect for fine cutting and emulsifying

Microcut HD150

Perfect for fine cutting and emulsifying

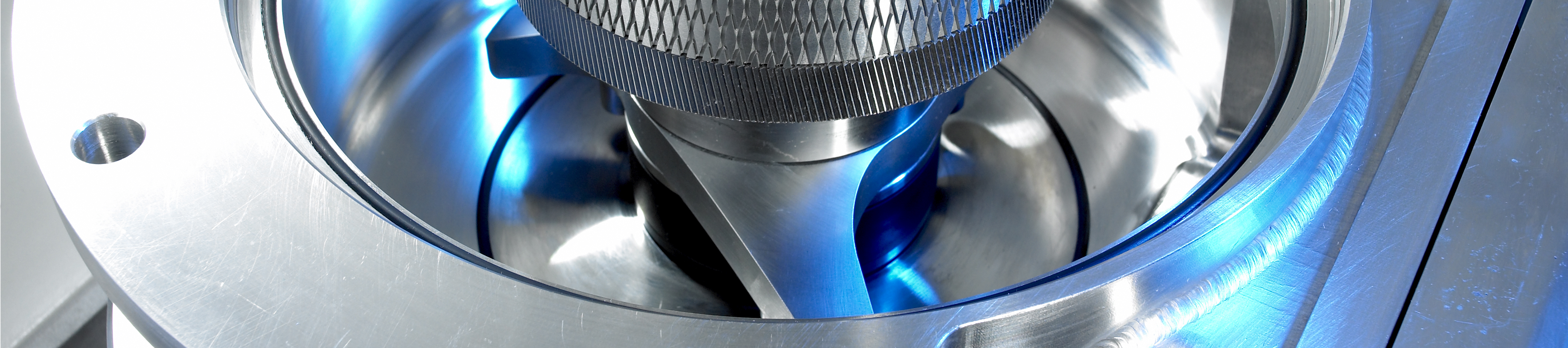

Perforated Disc Mill

Powerful grinding and pre-grinding

Tooth Colloid Mill

Variable wet milling

Corundum Stone Mill

Versatile wet milling and dispersing

Co-Ball Mill

High energy grinding and dispersing

PLANT-BASED DRINKS WEBINAR

March 27, 2024 – 9 am and 4 pm

Immerse yourself with us in the world of vegan beverage processing and learn more about the key technology of wet milling.